YOU ARE HERE » MICROWAVE DRYING SYSTEMS

Microwave Vacuum Drying Systems

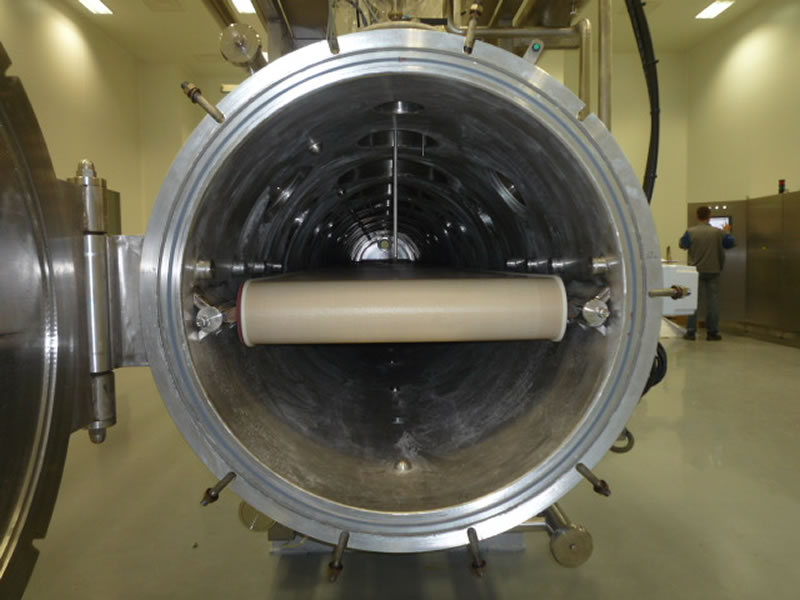

Microwave Vacuum Dryers combine two different technologies to create specific conditions for drying very sensitive products.

While Microwaves delivers gentle and uniform heat to the product a vacuum atmosphere allows using a lower drying temperature.

This drying technique is very well suited for the continuous drying of fragile and heat sensitive products without affecting quality.

Microwave Drying Chamber's

Microwave dryers are fast and preserve many of the original aspects of the product being introduced to the chamber.

Advantages of Microwave drying:

Low temperature

Low temperature

Short drying time

Short drying time

Absence of oxygen

Absence of oxygen

Sanitation - clean environment

Sanitation - clean environment

Increased product shelf life

Increased product shelf life

Greater nutritional retention

Greater nutritional retention

Higher anti-oxidative capacity

Higher anti-oxidative capacity

Microwave dryers are fast and preserve many of the original aspects of the product being introduced to the chamber.

Advantages of Microwave drying: